Injection moulded plastics engineering features

Overmoulding

I have designed several products with overmoulding of plastics and synthetic rubbers in different combinations. I have expertise in the compatibility and mouldability of these materials when combined to make a product part.

|  |  |  |

|---|---|---|---|

|  |

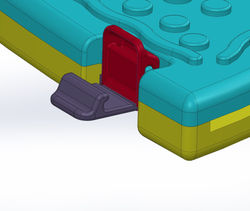

Snap fits

I am very experienced in the design of these useful features, integral in mouldings, taking advantage of the resiliency of most plastics, like Nylon, Acetal, Polycarbonate, ABS, Polypropylene and other plastics. I am able to carry out Finite Element Analysis to analyse their performance

Clamp for toyPrototype and injection moulded part with integral snap fit |  Urine sample collection funnelwith integral snap fits that engage on container below |  Engaged with containerThe snap fits allow for different container types |

|---|---|---|

Plastic tilewith integral snap fits that engage with receptacles below |  Tile undersideReceptacles that engage with snap fits |  Medical productwhich is entirely assembled with accurate snap fits |

Baby teetherwith integral snap fits having a moulded-in living hinge |  Medical product above3D printed prototypes to test mechanical features. |

Moulded-in elements

I am able to design mouldings with moulded-in elements such as threaded inserts, magnets, anchors and other mechanical parts

Silicone pouch with moulded-in magnets |  Strap with magnets to attach the pouch |

|---|

Design to prevent sink marks

Apart from knowing the necessary design features, to prevent sink marks, I carry out computer analysis to observe where there is a risk of sink marks and distortions which can appear after making costly moulds.

Sink marks analysis |  Warp analysis |

|---|

Demoulding provisions

These consist of the necessary design features to be able to remove the part from the mould, automatically, after it has cooled down.

Analysis to seek so called 'undercuts'that can catch the part in the mould, preventing it from being ejected |  Analysis to check the walls angles(draft angles) to allow the part to come off the mould |

|---|

Integral hinges

Materials like Polypropylene and Polythene allow the creation hinges, integral in the part, which can be used to provide useful features like lids, snap fits and other elements.

Snap components with integral hinges |  They are folded with the hingeto snap on a part made of cloth in this instance |

|---|

Spring design

Using the mechanical strength and resiliency of plastics like Acetal, Polycarbonate and Nylon, I am able to design integral springs that will last many cycles. I carry out Finite Element Analysis to design them.

Components with integral springs |  FEA analysis to determine weak areasWith this analysis the design of the part can be adjusted to reinforce the part against breakage. |

|---|

Moulded threads

I know the necessary design detailing to be able to mould threads whilst it is possible to remove the part from the mould.

Moulded threads, such as on bottles |  Fine CAD detailing of threadsThis can include sealing against escape of liquids. |

|---|

Design to integrate features avoiding side cores

Even though side cores are useful, and often used, in injection moulding it is more economical to design features that avoid them and the moulding of them is done with the two halves of the mould.

Product using linked plastic mouldingsThese are the green parts, designed to be made with the two halves of the mould, only, whilst having features that would require side cores if no creative thinking is used in their design. |  Design of features to avoid side cores |

|---|

Mechanical components

Knowing the use of engineering plastics, which can carry out the functions of metals, is very useful when the product will be made in mass production as it avoids the costly processing of metals, such as CNC machining, castings and the like. Moulding engineering plastics also helps design complex parts which cannot be made in materials and processes such as sand castings, sheet metal, wood and others.

Dispensing deviceAlmost all metal part are replaced with engineering plastics |  Holder of 3D glasses to prevent theftStrong mechanical parts to be made in injection moulded engineering plastics. |

|---|